A critical item in a supply chain is an inventory material with an exceptionally low level of redundancy within the production process. These items are typically linked to specific functional locations (physical areas within a plant) or functional equipment (machines or components crucial for production).

Disruptions in the supply of critical items can cause:

- Major production stoppages: If a critical item is unavailable, it can halt or significantly slow down production in the linked functional location or using the dependent functional equipment.

- Significant financial losses: Delays or shortages of critical items can lead to lost production time, missed deadlines, and potential customer dissatisfaction, impacting profitability.

- Unmitigated safety or environmental risks: In some cases, critical items might be essential for maintaining safe operations or preventing environmental hazards.

Key Characteristics of Critical Items:

- Low Redundancy: There are few or no readily available substitutes or alternative solutions in case of a stockout.

- Functional Location/Equipment Link: These items are often directly tied to the operation of specific functional locations or functional equipment within the production process.

- High Impact on Business Continuity: Disruptions in the supply of critical items can significantly disrupt overall production, leading to financial losses and potential safety concerns.

- High Service Level: Assigning a critical item classification typically triggers a higher service level percentage within the inventory management system. This service level percentage reflects the desired level of stock availability for the critical item, aiming to minimise the risk of stockouts and disruptions, resulting in holding higher stock levels on average compared to non-critical items.

- Frequent Cycle Counting: Due to their high impact on operations, critical items are typically subjected to more frequent cycle counting compared to non-critical items. Cycle counting is a physical inventory verification process that helps ensure the accuracy of inventory records and minimize the risk of stockouts. By performing more frequent cycle counts on critical items, companies can gain a more precise understanding of their on-hand inventory levels and take proactive measures to prevent stockouts and potential disruptions.

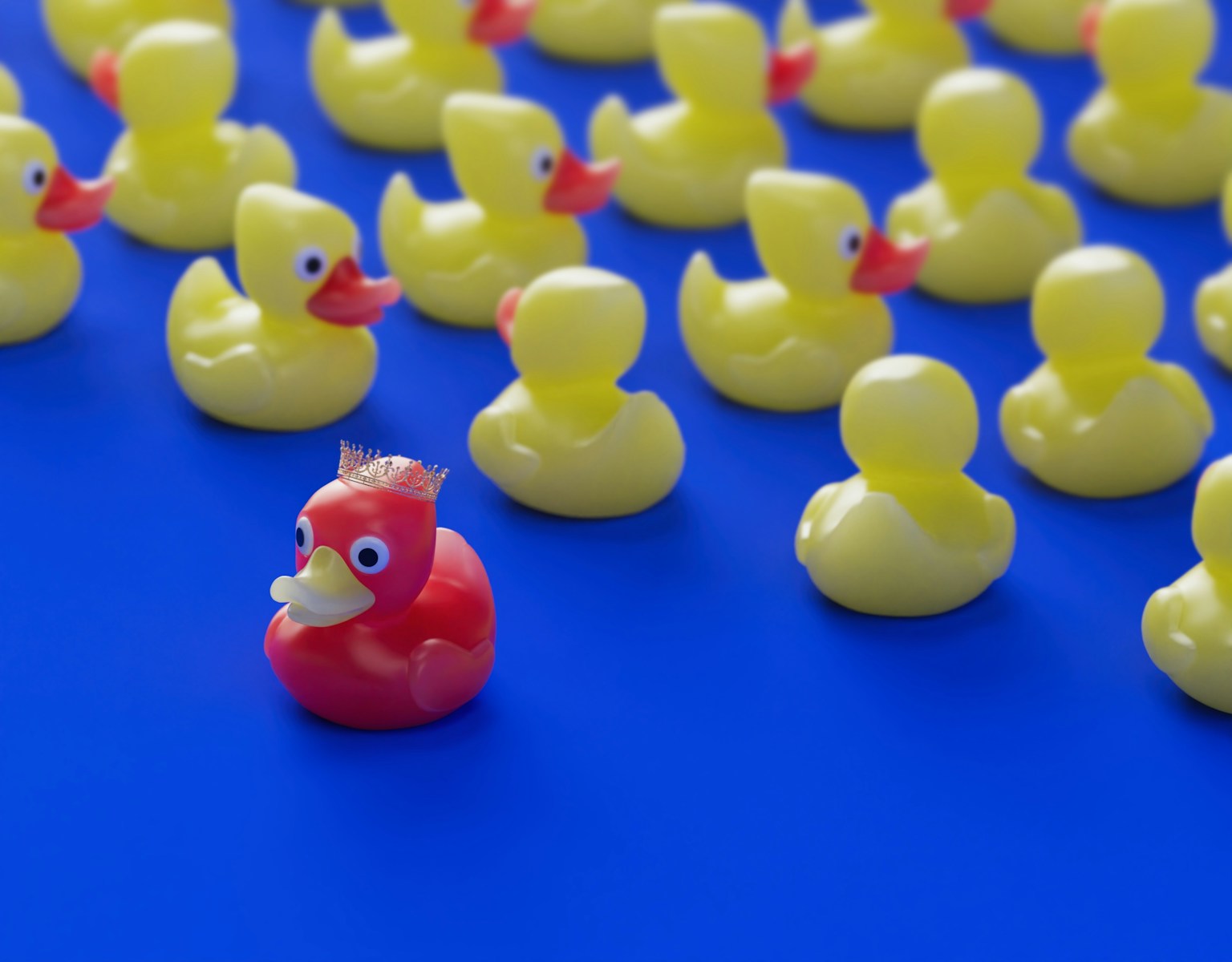

Flagging a Critical Item:

Due to the financial impact associated with a critical item’s elevated service level percentage and potentially higher stockholding costs, the designation requires a joint approval process:

- Competent Engineer Approval: A competent engineer specialising in the relevant field must assess the item’s technical importance and potential consequences of disruption. Their approval ensures a clear understanding of the item’s role within the production process and its impact on functionality.

- Inventory Manager Approval: The inventory manager, considering the financial implications of a higher service level and potential stockholding increases, reviews the engineer’s assessment. Their approval ensures a balance between mitigating disruption risks and managing inventory costs effectively.

By implementing this two-tiered approval process, companies can ensure critical items are accurately identified based on both technical necessity and financial considerations. This collaborative approach helps optimise inventory management and safeguard business continuity.

Examples of Critical Items:

- Specialised spare parts for critical production equipment.

- Unique raw materials required for a specific product without readily available substitutes.

- Safety equipment crucial for maintaining safe operations in a particular functional location.

By effectively identifying and managing critical items, companies can minimise supply chain disruptions, ensure smooth production processes, and safeguard their financial and operational performance.