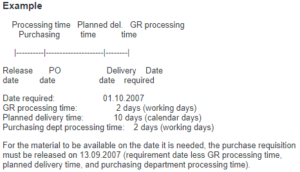

In Material Requirements Planning (MRP), it’s crucial to consider not just the Quantity of materials needed but also the Timing of those needs. Focusing on the time-dimension ensures efficient and effective planning.

Highly Simplified Example Scenario

Two reservations are made for the same item, at the same time:

- Reservation 1: Needed in 2 weeks

- Reservation 2: Needed in 6 months

With a 10-day lead time, SAP schedules replenishments accordingly:

For Reservation 1, the purchase order is triggered to ensure the item is available within two weeks.

For Reservation 2, the purchase order is triggered closer to the six-month requirement date, ensuring just-in-time delivery. For the untrained eye, or for the analysis models that only consider the “Quantity” dimension, this will look like a “Stock-out” situation, but clearly it is not.

Why Timing Matters

Avoiding Overstock and Understock:

Ordering based on timing prevents excess inventory and shortages, aligning supply with demand accurately.

Optimising Storage and Costs:

Timely orders reduce storage and handling costs, and minimise the risk of damage or obsolescence.

Enhancing Cash Flow:

Funds are allocated efficiently by purchasing materials only when needed.

Integrating the time dimension into MRP ensures materials are available when needed, optimising inventory levels and operational efficiency.

SAP’s sophisticated scheduling capabilities demonstrate the importance of considering both time and quantity for a responsive and efficient supply chain.